Understanding And Using Desensitizing Ink

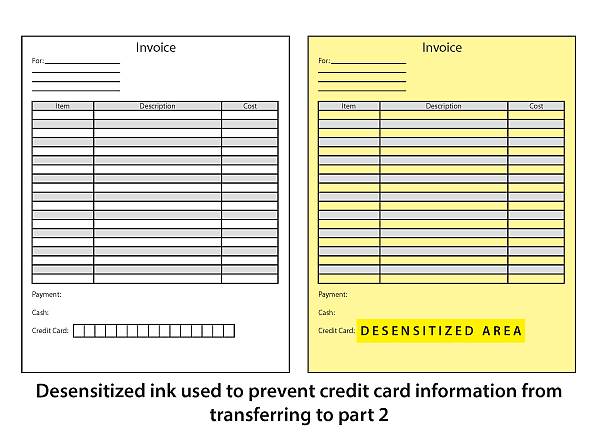

Sometimes it is imperative in a carbonless form design to have an area that does not reproduce from part to part. This area could for instance, contain a credit card number, a prescription or a social security number. To achieve this goal desensitizing ink is sometimes utilized in the area that has been chosen to not reproduce from part to part. Desensitizing ink is not analogous to spot carbon because it can only be used to block transfer in an area not to facilitate the transfer.

Ink

Desensitizing ink is composed of various compounds that neutralize the Lewis acid which is encapsulated on the coated face (CF and face of CFB) of the paper. Some of the inks incorporate varnish to accomplish this. When pressure is applied in a desensitized area, no transfer should take place from part to part. Coloring such as titanium dioxide is added to the ink to make it visible to the press operator. The ink appears white and has a distinctive smell.

Design Considerations

When designing a form that uses desensitizing ink several considerations should be kept in mind. The area to be desensitized should be set at 100% density. You can either create a specific desensitized ink in your design software or you can just choose a color such as yellow to represent the ink. With desensitizing ink less is more. It is best to keep the desensitized area to less that 40% of the total surface area of the form. The more ink you lay down the more likely you are to get offsetting or scumming and desensitize areas that you did not intend to. It is cheaper to utilize an additional plate with a block out pattern than to add a plate and desensitizing ink if your objective can be achieved by obfuscation of the information.

On The Press

On the press the print tower closest to the front of the machine is best for desensitizing ink. It is difficult to print on the area that has been desensitized so it is best to lay this ink down last. Because of the white color of the ink you must clean the ink tower it is used in thoroughly; otherwise the last ink used will tint the ink. Some plates will not stand up to desensitizing ink. If possible you may want to acquire a sample of the ink to test with your plates. If your plate is able to be utilized with desensitizing ink you will need to carefully maintain the correct ink and water balance. Desensitizing ink usually requires more water than a typical offset ink. If you lay the ink down too heavy it will offset or scum and possibly cause transfer issues in other areas of the form.

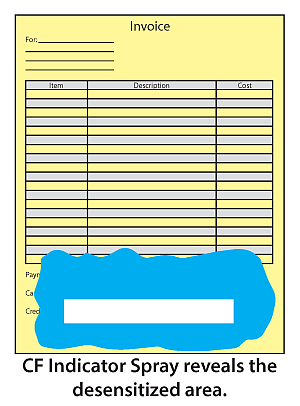

To test the desensitized area wait for 5 minutes to allow ink to set on form, then use a coated back (CB) paper to test for mark through. Some press operators use CF Indicator Spray from Appleton (Appvion) Paper to check the desensitized area.

Desensitizing ink is a relatively easy way to prevent transfer from part to part of a carbonless form if the guidelines above are followed.

Disclaimer

This information is provided for our trade partners so that they can understand the various aspects of carbonless forms printing. Desensitizing ink is used at SEF, Inc., on our Didde offset presses in this manner. Your equipment may vary and no guarantee is made that this will work on your press. Certain types of rollers (e.g. polyeurethane) plates and fountain solutions may not work well with desensitizing ink. Remember to check with your parts and ink vendors as to the suitability of their product on your machine.